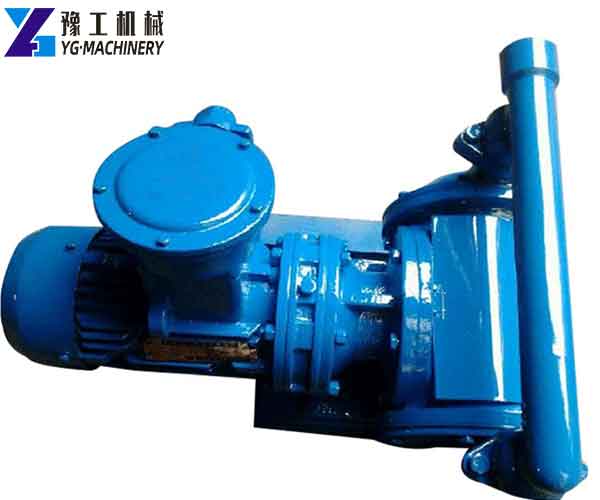

Electric Diaphragm Pump

Piston Diaphragm Pump

The electric diaphragm pump is driven by a cycloidal pinwheel reducer, and the double diaphragm is reciprocated by the crank slider mechanism so that the volume of the working chamber is alternately changed to continuously suck and discharge the liquid. At the same time, in recent years, due to the breakthrough progress of the diaphragm material, and the great extending the service life of the diaphragm, it has been more and more widely replaced by some centrifugal pumps and screw pumps for petrochemical, ceramic, metallurgical, and other industries. The electric diaphragm pump is a new type of pump, which is characterized by no need for priming water and strong self-priming ability.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Electric Diaphragm Pump Application Field:

The diaphragm pump in the paint and ceramic industry has occupied an absolutely dominant position; environmental protection, wastewater treatment, construction, sewage, and fine chemicals are expanding their market share and have irreplaceable status as other pumps.

The working principle of the electric diaphragm pump is relatively simple, and the motor drives the diaphragm on the left and right ends of the plunger to reciprocate one by one through the reduction box. In the left and right pump chambers, the movement of the upper and lower one-way ball valve diaphragms causes a change in the volume in the working chamber, forcing the four one-way ball valves to alternately open and close, thereby continuously sucking in and discharging the liquid.

Product Technical Parameter:

| model | Flux | suction | lift | exit pressure | Rated Power | operating temperature | Pump suction discharge aperture | ||

| cast iron | stainless steel | ||||||||

| 15 | 0.75 | 3 | 40 | 4 | 0.55 | 100 | 150 | 115 | |

Diaphragm Pump

Best Diaphragm Pumps

The Performance Characteristics of the Electric Diaphragm Pump:

- No need to irrigate water, with a self-priming capacity of more than 7 meters.

- Through good performance, particles, mud, etc. A diameter of less than 10mm can be passed without difficulty.

- Since the diaphragm will be separated by the conveying medium and the transmission mechanical parts, the medium will never leak out. Moreover, the pump itself has no shaft seal and the service life is greatly extended. According to different media, the diaphragm can be divided into neoprene rubber, nitrile rubber, fluorine rubber, tetrafluoroethylene, etc., which can fully meet the requirements of different customers.

- The flow medium of the pump body can be divided into cast iron, stainless steel, and aluminum alloy according to user requirements. The motor is divided into two types: ordinary and explosion-proof.

The Main Purpose of the Electric Diaphragm Pump:

- A variety of highly toxic, flammable, volatile liquids.

- A variety of strong acids, strong bases, and strong corrosive liquids.

- It can transport medium at higher temperatures (150 °C).

- As the pre-stage pressure feeding device of various filter presses.

- Hot water recovery and recycling.

- Tank truck, oil depot, oil loading, and unloading.

- Pump suction applesauce, mashed potatoes, chocolate, etc.

- Pump paint, gum, pigment binder.

- Various porcelain glaze, cement grout, mortar, and mud.

- Various rubber latex, organic solvent, and filler.

- Use the pump to clear the warehouse and the remaining oil from the cruise barge.

- Hops and baking powder slurry, syrup, molasses.

- Pumping sewage, and sediment in mines, tunnels, and sewers.

- The suction of various special media.

New Type Electric Diaphragm Pump

High-Quality Electric Diaphragm Pump

Electric Diaphragm Pump Operating Procedures:

The preparation before starting:

- Check the oil quality and oil quantity in the pump ( the oil tank horizontal line in the transmission box is correct, and the three-valve oil cup and diaphragm cavity should not be lower than the red indicator line).

- Check whether the welds on the inlet and outlet pipes, the bolts at the joints, and the performance of the sealing surface are in good condition, and check whether the suction and discharge pipes of the pump are unlocked.

- Before starting the pump for the first time, the coupling should be driven several times, and there must be no jamming. The rotation direction of the inspection station motor is consistent with the cutting on the pump.

- The pump should be operated adaptively, especially if it is parked for more than 5 days. It must be started from the “0” stroke when starting. ( the short-term stop pump can be started at any position.) After 5 minutes of no-load operation, adjust the piston stroke to the desired position, and perform the load operation.

- Pressurization operation: close the bleed valve in the three-valve oil cup of the diaphragm pump, and gradually increase the pressure at the rated pressure.

Normal Operation:

- During normal operation, the hand touch of the plunger seal is not hot and does not leak. The oil temperature in the transmission case must not exceed 650℃。

- Always check the oil level and oil quality in the three-valve oil cup to meet the requirements, and observe whether the oil surface is fluctuating. If the fluctuation is found, the valve will leak.

- After adjusting the safety valve, it is forbidden to turn the adjusting screw. Do not touch the fill valve ball to keep the oil in the three-valve oil cup clean.

- Always check the feed liquid temperature (generally≤1000°C), and the pump liquid pressure(≤ rated pressure).