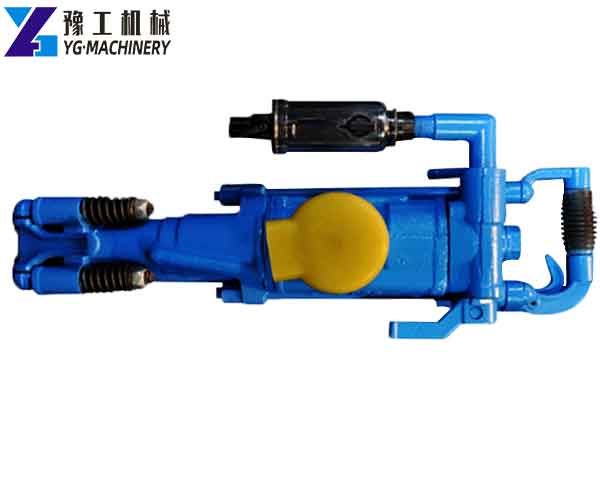

Pneumatic Rock Drilling Machine

The pneumatic rock drill for sale in YG Machinery is a kind of highly efficient rock drilling machine. It is widely used in rock roadway digging and drilling blasting holes in various rock drilling machines. It is an important tool in stone works, such as mining, railway, transportation, water conservancy construction, and so on. This machine has a wide range of applications. It can be used to drill horizontal or skewed horizontal or skewed blasting holes on medium-hard or hard rocks with a drilling depth of up to 6 meters. According to its power resource, rock drilling machines can be divided into gasoline rock drilling machines, hydraulic rock drilling machines, pneumatic rock drilling machines, and electric rock drilling machines.

YG Machinery is a professional drilling rig manufacturer, so we have many different types of drilling rigs, hydraulic water well drilling rigs, core drilling rigs, small water well drilling rigs, backpack drills, crawler drilling rigs, truck drilling rigs, trailer water well drilling rigs, anchor drilling rigs, down-the-hole drilling rigs, horizontal directional drilling rigs, rotary drilling rigs, etc. Contact us for a quote.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Pneumatic Rock Drill Machine

Air Leg Rock Drilling Machine

Technical Parameter of Pneumatic Rock Drill for Sale

| Model | YT28 |

| Opening hole diameter | 28-42mm |

| Drilling hole depth | 0.5-6m |

| Cylinder bore | 80mm/60mm |

| Pipe diameter | 13mm/25mm |

| Water pressure | 0.2-0.4mpa |

| Wind pressure | 0.4-0.63mpa |

| Impact frequency | ≧37Hz |

| Size | 661*247*195mm |

| Weight | 28kg |

The Working Principle of Pneumatic Drilling Machines:

The rock drilling works according to the principle of impact crushing. During operation, the piston does high-frequency reciprocating motion and continuously impacts the shank. Under the influence of impact, the rock is crushed and chiseled into a certain depth by the wedge-shaped brazing head, forming a notch. After the piston is retracted, the drill turns a certain angle, the piston moves forward and when the hammer tails are impacted again, a new dent is formed. The fan-shaped rock between the two indentations is sheared by the horizontal force generated on the brazing head. The piston continuously impacts the brazing tail and continuously inputs compressed air or pressure water from the central hole of the braze to drain the slag out of the hole, that is to say, a circular hole with a certain depth is formed.

Pneumatic Rock Drill Manufacturer

The Advantages of Pneumatic Rock Drill Machine:

- Lightweight and less gas consumption, especially suitable for mobile operation with a small air compressor. Lightweight causes lesser tiredness in the worker.

- The operation is simple, has gas-water linkage, easy to maintain.

- More economical. Pneumatic tools do not have electric motors which are more economical than electric machines.

- Robust and long-lasting, energy-saving and high efficiency, high generality, and high reliability.

- The pneumatic rock drill machines can be used in sites where electricity does not exist.

- These machines can also be conveniently utilized in moist environments, where the use of electric-powered devices may not be safe.

The Pneumatic Rock Drilling Machine Use Skills:

- When the pneumatic rock drilling machine is used, it is required to dry the compressed air at the air inlet of the rock drill and it is required to use clean soft water. When forced to use alkaline or alkaline water, some lubricating oil should be injected immediately after the drill is finished and the operation of the machine with water off should be carried out for a short time.

- When the new machine is started, it should be cleaned and reassembled. After reloading, drive the empty car and check if the operation is normal.

- Make the pipeline cleaning, routine disassembly, and maintenance so that the machine is always in good working condition. Operators should always pay attention to adding lubricating oil. It is forbidden to work without oil.

- In operation, please turn on the air before opening the water, and turn off the water before turning off the air. And pay attention to the water pressure which should be lower than the wind pressure to prevent the water from flowing backward into the cylinder of the rock drill machine, destroying the normal lubrication of the machine and affecting the normal operation of the machine.

- When the drilling machine is slow to rotate, it should immediately reduce the axial force of the air leg through the pressure regulating valve. If the fiber rod does not turn, the axial thrust of the air leg is invalid, the rock drill machine should be stopped immediately and the rock restarts the machine after troubleshooting.

- Observe the powder discharge of the machine. The air leg rock drill is not allowed to remove the water needle for operation or dry hole drilling.

- When the telescopic rock drill is working upwards, it should be noted that the magma flowing down the drill should not be close to the sleeve and the spacing should be at least 20mm. Otherwise, the blowing force is insufficient. At this time, the blowholes on the jackets should be checked according to the procedure to see if the blowing holes are unobstructed.

- When the telescopic rock drill is working upwards, in addition to complying with the general safety technology of rock drilling work, it is also necessary to pay special attention to the sudden breaking of the drill to prevent accidents at work. It is strictly forbidden to run at full speed for a long time and the trolley should be driven when the fiber is extracted.

- After the work is finished, close the water valve to make the rock drill machine run for a short time with a small wind to remove the accumulated water, which can prevent corrosion.

- For the guide rail type rock drill machine, when a fiber is finished, the wind should be stopped, and then the unloading tail should be reversed.

- When the rock drill machine is stopped use for a long time, it should be removed and cleaned in time, coated with anti-rust oil, and stored in a dry place.