The pneumatic grout pump uses compressed air as the power source, and the cylinder and the grouting cylinder have a larger ratio of the working area so that the cylinder can generate a higher injection pressure with smaller air pressure.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Pneumatic Grout Pump Parameter:

| Model | YG-ZBQ50/4 | YG-ZBQ70/7 | YG-ZBQ24/10 | YG-ZBQ40/11 |

| Rated rate | 50 | 70 | 24 | 40 |

| Rated pressure | 4 | 7 | 10 | 11 |

| Weight | 18 | 85 | 40 | 83 |

| The number of reciprocations | 0-60 | 0-60 | 0-60 | 0-60 |

| Supply pressure | 0.2-0.65 | 0.2-0.65 | 0.2-0.65 | 0.2-0.65 |

| Dimension | 1000*505*645 | 1050*480*780 | 1040*500*730 | 1200*600*800 |

| Air compressor | 0.7m³ | 1.5m³ | 0.7m³ | 1.5m³ |

Scope of Application:

A pneumatic grouting pump is suitable for grouting and water blocking, filling voids, and reinforcing broken rock layers in mines, tunnels, water conservancies, subways, buildings, bridges, and other construction sites.

Use of Pneumatic Grouting Pump:

Pneumatic grouting pumps are mainly used for waterproofing, reinforced grouting projects in coal mines, iron mines, etc., as well as grouting and water blocking in subways, tunnels, water conservancy, construction, etc. The pump uses compressed air as its power, featuring a small size, lightweight, and no overload. It can be safely used in places that are flammable, explosive, strong magnetic, radiation, dusty, temperature change, and water spray.

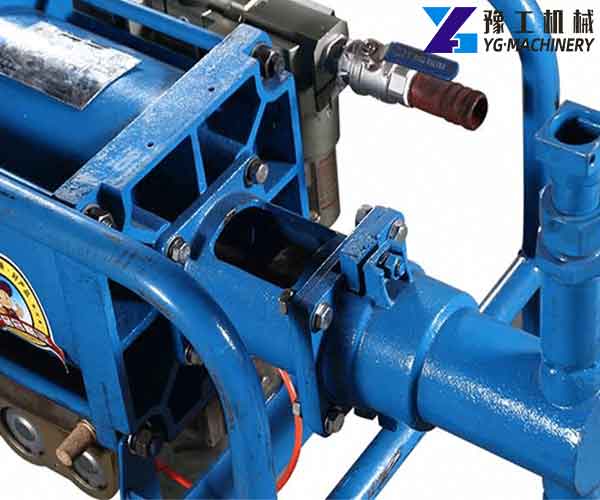

Basic Structure:

The basic structure of the pneumatic grouting pump is mainly composed of a pipe rack, cylinder, piston, end cover, joint box, liquid cylinder, inlet, discharge slurry tank, reversing valve, and some auxiliary parts.

Working Principle:

The YG-ZBQ pneumatic grout pump compresses the air through the ball valve, the gas source two-connected body and the two-position five-way reversing valve enter the cylinder to push the cylinder piston to reciprocate. Because the cylinder rod is connected to the slurry rod, the cylinder piston reciprocates and also pushes the cylinder piston to reciprocate to complete the suction and discharge action. The reversing direction is set by the dial on the cylinder rod, the stroke valve is toggled back and forth, the reversing valve is controlled to change the direction of the cylinder to enter and exhaust, and the reciprocating motion of the cylinder piston is continuously completed.

Advantages of Pneumatic Operated Cement Grout Pump:

- The pump has an advanced structure, high-rated output pressure, large displacement, and high efficiency, easy to move, and convenient to use and maintain.

- Full-featured, that is, the one-component slurry can be injected, or two-component slurry can be injected; it can be injected with chemical slurry or another slurry such as cement; each cylinder works synchronously, the mixing ratio can be adjusted, and the mixing is uniform; it can be used as an emulsion pump, hydraulic pump, etc. for other applications.

- It has good safety and can be used safely and can be used safely in places with high flammability, explosion, temperature, and humidity changes.

- The parameters can be adjusted according to the different needs of customers. Meet different pressure, flow, and special requirements of different conveying media.

- It can work in a three-cylinder or two cylinders to achieve the slurry mixing ratio of 4:1 or 1:1. The pump has high pressure and a large output flow, which can meet the high-intensity injection.

Precautions for Use:

- The pneumatic grouting pump must be equipped with the flame retardant antistatic hose in the underground coal mine!

- Pneumatic grouting pump when the intake hose and the pump valve are connected, they must be bundled firmly to avoid taking off the injured!

Instructions:

1. Preparation Before Pumping:

- The pump should be placed horizontally, 30# oil should be injected into the oil mist to the upper engraving line, and a little oil should be dripped on the moving parts such as the plunger and the stroke reversing valve ejector.

- Adjust the filter pressure-reducing valve to the required air supply pressure according to the characteristic curve. ( pressure and discharge pressure about 1:10 ).

2. Operation in Grouting

- The pump has an automatic control performance, which can automatically adjust the amount of slurry. During the grouting process, no artificial adjustment is required. If the amount of grouting needs to be changed midway, the opening size of the ball valve can be adjusted.

- When the oil mist is lowered to the lower scale, the oil should be immediately replenished to the upper scale line, and the water in the filter cup should be drained in time.

- During the grouting process, it cannot be stopped in the middle, especially when paying the double liquid.

3. Maintenance After Stopping the Pump:

- After the grouting is completed, immediately open the ball valve after the grouting device to release pressure, put the call tube into the clear water tank, and pump the pump to wash the residual pump liquid. If the pump is deactivated for more than 24 hours, it should be removed into the volleyball valve, and the piston apron, completely removing residual pump slag, oil, and rust.

- The valve ball and valve seat of the pump and grouting device has a service life of about 50,000kg of the cement slurry. The disassembly and assembly of consumable parts are very simple, and the pump has a small amount of maintenance and low use cost.

- When installing the nut of the tie rod and the piston, pay attention to tightening the real part and tightening the back cap. Otherwise, the impact sound will occur when the working pressure is high. When the cylinder head is installed, the nut should be tightened repeatedly. The joint planes should be kept flat to ensure concentricity after assembly. When installing the “O” type seals of all parts, it should be noted that the mating surface should be smooth and free of sharp corners to prevent damage to the seal.

- When loading the rod “V” type sealing ring, pay attention to the fact that each piece is solid, the groove should be in the direction of pressure. When pressing the back screw of the “V” ring, it should not be too tight, otherwise, the “V” type rubber ring will be worn out very quickly.

- The vents of each pneumatic component are directional and should be taken care of when disassembling and disassembling, otherwise, it will not work.