The hose pump belongs to the peristaltic pump category. The peristaltic pump is a kind of rotor-type positive displacement pump, and its working principle is similar to that of the digestive tract in the peristaltic manner of conveying gas, solid, and liquid three-phase medium.

The designer and user of the hose pump are primarily concerned with its ability to deliver highly abrasive media. It has no valve and no seal. The only part that comes into contact with the medium is the inner cavity of the rubber hose. The rotor of the compression hose is completely independent of the medium.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Industrial Hose Pump Parameter:

| Hose Pump Parameter: | ||||

| Model | YG-32 | YG-40 | YG-50 | YG-60 |

| Flow

(m3/h) |

≤1 | ≤2.5 | ≤6 | ≤15 |

| Pressure (Mpa) | 1 | 1 | 1 | 0.8 |

| Power

(kW) |

0.5 | 2.2 | 4 | 4-5.5 |

| Distance (m) | 30 | 35 | 40 | 45 |

| Reducer | 2# | 2# | 3# | 4# |

| Weight (kg) | 120 | 190 | 290 | 510 |

| Hose Size (mm) | ∅66*∅32*1030 | ∅66*∅38*1150 | ∅84*∅51*1400 | ∅100*∅64*1750 |

| Dimensions (mm) | 750*700*550 | 900*700*650 | 1000*900*800 | 1400*1100*1100 |

The Uniqueness of the Hose Pump:

No other pump has better self-priming ability than the hose pump, it can produce a perfect vacuum to absorb liquid; It can transport gas-containing liquid, and foam liquid without gas resistance; The shear-sensitive medium is also a strong item; It is a natural metering pump regardless of the fixed displacement per revolution and independent of the outlet pressure.

Working Principle of Hose Pump for Sale in YG:

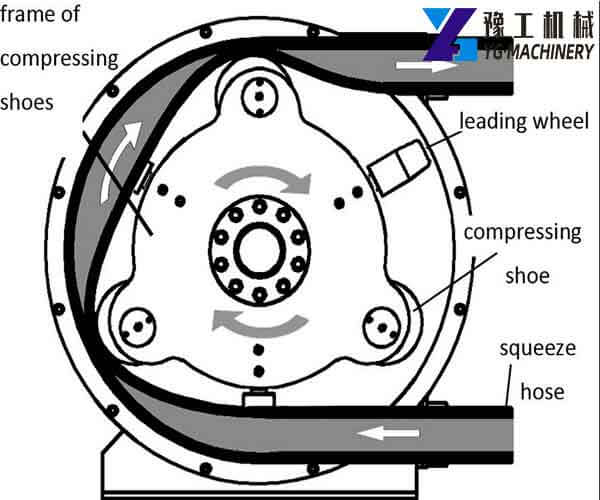

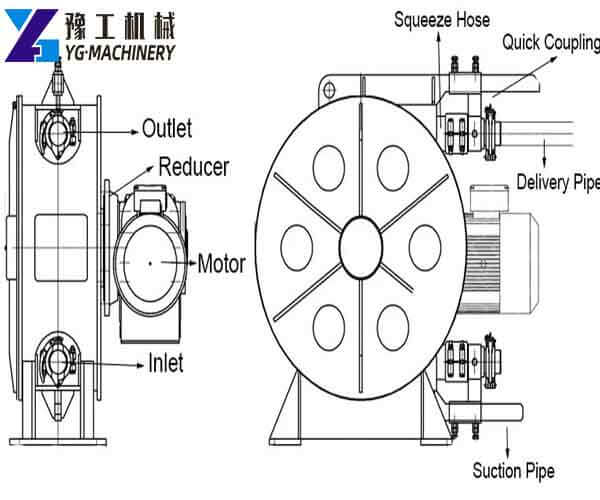

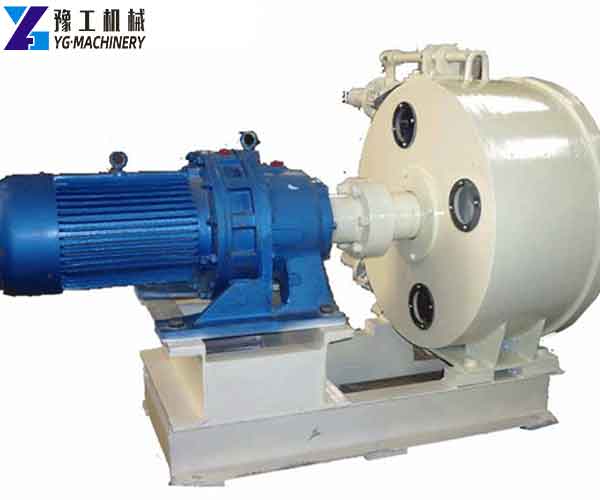

The reinforced hose is arranged in a U shape in the pump body. When the slewing frame drives the squeezing wheel to rotate, the hose is elastically deformed by the back pressure of the squeezing wheel, negative pressure is sucked into the suction port to suck the slurry, and the push slurry is pushed through the squeezing wheel. The material is discharged from the discharge port to form a pressure transfer of the slurry. It can be used in construction, mining, food, paper, ceramics, and other suitable fields for long-distance conveying, metering pumping, pressure injection ( irrigation ), material conveying and spraying, etc. It completely eliminates the traditional pump impeller and shafts the sealed operation mode has great advantages for medium transportation with large viscosity, high corrosivity, and large fluid impurities. It is a completely different principle from the traditional pump and has a wide application range.

The transmission drives the rotor to rotate. The two pressure rollers distributed on the rotor 180°continuously roll along with the hose inside the pump to crush the hose. Under the force of its own elasticity and the guide roller, the tube is restored to its original state. At this time, a high vacuum is generated in the tube to suck the fluid material into the lumen, and the fluid entering the lumen is discharged from the tube under the action of the accompanying pressure roller. As a result of this cycle, the material is continuously sucked in and discharged.

Application Area:

- Chemical industry, various anti-corrosion pastes, and inorganic salt materials.

- Oil, drilling, water treatment, mud, lime slurry.

- Filling materials for mining and metallurgy, slurry transportation.

- The food industry, oil materials, beverages, and paste material transportation.

- The paper industry, pulp, and sulfur transportation.

- The construction industry, cement mortar, foam concrete production line, roofing house foam light fluid materials; tunnel application, subway construction application, pumping pulp, food emulsion pumping, floor reinforcement construction, wall spraying mortar construction, pumping mud, and other working conditions.

- Paint, titanium dioxide, carbon dioxide, and other materials are transported.

6 Advantages of the Hose Pump:

- It is easy to install, simple to operate, and can run continuously for a long time.

- The pump sends a variety of fibers and slurry, shear sensitivity, the abrasive or gas-liquid-solid mixture is a perfect choice, and the material diameter is greater than ≤4-6mm.

- It can easily pump internal fluid erosion, high viscosity, high-density fluid, and paste fluid.

- The hose pump does not need to replace the seals, gaskets, impeller rotors, stators, or traditional various pump components.

- The movement of the pump is divided into positive and clockwise rotation without backflow and siphon phenomenon, and has the function of the shut-off valve; in reverse, the fluid can be sent out and sucked back.

- The pumping fluid is proportional to the speed and can be accurately measured.

Installation Precautions:

- The pump should be placed smoothly to reduce vibration and reduce noise.

- There is a flexible or rigid short section ( about 80~100cm) between the outlet flange of the hose pump and the pipe connection to replace the hose.

- The installation height of the pump can be above the material plane, and there is no need for auxiliary pipelines and starting facilities, but the height difference should not exceed 20 meters.

- Under the condition that the conveying medium has a high viscosity, large particles, easy deposition, and poor fluidity, the pump is generally installed under the material.

- When using the pump, care should be taken to minimize the elbow ( especially the right-angle elbow ).

- The inlet and outlet of the pump are not allowed to install a check valve.

- The pump outlet of the hose pump should be equipped with a pressure gauge to monitor the pump’s movement.

- The inlet and outlet of the pump are in the same direction as the pump, and the inlet and outlet of the pump are interchangeable, which is determined by the user according to the piping and the actual situation.

- Electrical installation should be equipped with positive and negative buttons for maintenance, pipe replacement, and self-cleaning.