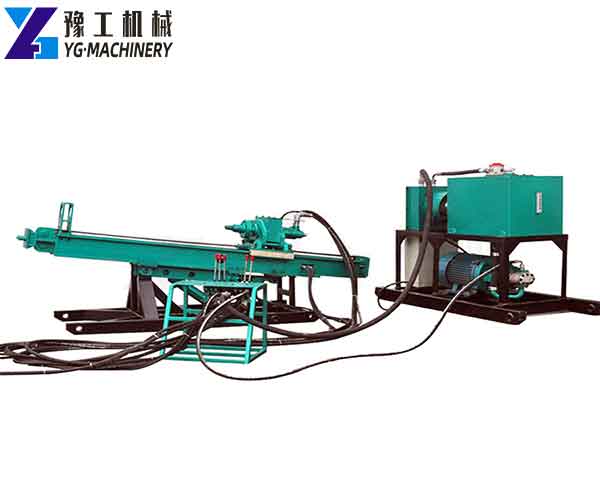

The anchor drilling rig is mainly used for slip wave treatment engineering of railways, highways, water conservancy, and hydropower facilities, the anchorage engineering of the dangerous rock mass, the anchorage engineering of rock slopes such as controlling the displacement of buildings, and the deep foundation pit support and foundation for construction city. Reinforced engineering holes, blasting holes for blasting works, and tunnel pipe support holes. Good performance: compact structure, small size, lightweight, flexible, can be applied to work on high slopes and scaffolds; hydraulic powerhead has large output torque, strong drilling capability, and a wide range of drilling rigs; the output speed of the powerhead is step-less speed change, and the drilling parameters can be selected independently according to different construction requirements and geological conditions to achieve the best drilling efficiency. Therefore, no matter what type of anchor drilling machine, the hydraulic transmission system is an important part of the anchor drilling rig equipment. In YG Machinery, you can find the right machine for you.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800

Parameter of YG Best Anchor Drilling Rig:

| Model | YG–MG40 | YG–MG50 | YG–MG70 |

| Hole depth(m) | 10-60 | 25-70 | 35-80 |

| Hole diameter(mm) | 90-180 | 90-165 | 90-200 |

| Rod spec(mm) | Φ76*1500 | Φ76*1500/ Φ89*1500 |

Φ76*1500/ Φ89*1500 |

| Hole angle | 0-90° | 0-90° | 0-90° |

| Output rotary speed(rpm) | 90 | 70 | 70 |

| Rated output torque(N*m) | 2400 | 2500 | 3900 |

| Powerhead max stroke(mm) | 1800 | 1800 | 1800 |

| Max lifting force(KN) | 25 | 30 | 35 |

| Powerhead max feeding force(KN) | 20 | 25 | 25 |

| Hydraulic system-rated pressure(Mpa) | 16 | 17-18 | 17-18 |

| Rotary electric power | 4-pole/7.5kw | Hydraulic | Hydraulic |

| Oil pump electric power(kW) | 4 | 22 | 22 |

| Electric voltage | 380v | 380v | 380v |

| Weight(kg) | 1000 | 1260 | 1460 |

| Hydraulic station dimension(mm) | 640*600*580 | 1850*780*1360 | 1850*810*1280 |

| Dimension(mm) | 2800*800*1400 | 3000*780*1360 | 3100*1000*1500 |

Crawler Anchor Drilling Rig

| Model | YG-150C | YG-150D |

| Main Parameters | ||

| Drilling Diameter (mm) | Φ150-250 | |

| Drilling Depth (m) | 130-170 | |

| Final hole diameter (mm) | 75 | |

| Drill pipe diameter/casing diameter (mm) | Φ73, Φ89, Φ102, Φ114 | |

| Drilling angle | 0-90° | |

| Rotator output speed (r/min) | 10/20/30/35/40/60/65/70/85/130/170 | |

| Rotator output torque (N.m) | 7500 | |

| Rotator travel (mm) | 3400 | |

| Rotor lift force (KN) | 70 | |

| Rotator lift speed (m/min) | 0-5 adjustable /7/23/30 | |

| Rotor pressure (KN) | 36 | |

| Rotator pressure rate 0-10 adjustable (m/min) | 0-10 adjustable /14/46/59 | |

| Walking parameters | ||

| Walking mode | Crawler walking | |

| Climbing angle | 25° | |

| Crawler Grounding Pressure (Kpa) | 36 | |

| Walking speed (km/h) | 20 | |

| Input power | ||

| Input power | Diesel 96Kw | Electric 55+18.5kw |

| Dimensions (mm) | 5400x2100x2000 | 5400x2100x2000 |

| Weight (kg) | 6500 | 6000 |

Classification and Characteristics of Anchor Drilling Rigs

- Full hydraulic anchor drilling rig.

The rotary power, propulsion power, and auxiliary actions of this type of drilling rig are powered by hydraulic pressure, and the hydraulic station is driven by a motor or an internal combustion engine. The rig has a wide adjustment range, a suitable aperture, and a deep hole depth; the opening and anti-clamping ability is good, and the operation is flexible and convenient, which is the type adopted by most domestic manufacturers. - Electric hydraulic clutch rig.

This type of drilling rig is powered by a motor, and the propulsion and auxiliary actions are hydraulically powered.

Safety Engineering Procedures for Anchoring Engineering Drilling Rigs

- Wear a safety helmet, lighting, and no alcohol before going to work.

- It is necessary to work for two or more people, and it is not allowed to work alone.

- Enter the work surface, first check the safety of the work surface, first discharge the top of the work surface, help the pumice, and the umbrella on the slope, and keep the ventilation in operation. The work site must be well-lit and the work lights should be illuminated with 36 volts.

- The work site should be kept flat and it is strictly forbidden to stack obstacles.

- Before work, it is necessary to check whether the equipment is placed stably and firmly, whether the screws of each part are well fastened, whether the lubrication parts are normal, and whether the drilling can be started according to the procedure.

- When lifting or dismounting the rig with the lifting tool, it must be carried out with a qualified wire rope button and under the command of a special person. The lifting bracket must be fixed firmly. When lifting the object, the personnel are not allowed to stay under the lifting object or in the offset direction to prevent danger.

- When two people carry the parts of the rig, they must have a good relationship with each other to prevent hand or lame.

- During the operation of the drilling rig, it is strictly forbidden to touch the anchor or the running part with your hands or gloves to prevent racking.

- When transporting the rig with the vehicle, the rig must be firmly fixed to the vehicle with the rope. When the vehicle is reversed, no one is allowed to stay on both sides or behind the vehicle to prevent crushing.

- When blasting, you should hide in a safe place to avoid the gun. When the gun is fired inside, it should be evacuated to the outside of the cannon or to the safe place designed by the commander to avoid the gun.

- It is necessary to drill at the designed workplace, and it is not allowed to go to other positions to prevent danger.

Pay Attention to the Following Items in the Maintenance Equipment:

- When connecting the oil pipes, all joints should be cleaned in clean kerosene. No particles or dirt are allowed.

- When installing the column, the sleeper should be installed on the top and bottom of the column. The sleeper should be parallel to the axis of the hole. The column should be placed vertically. After alignment, lock the thread buckle. No looseness or instability is allowed.

- The oil suction pipe is cut off. Only when the fuel tank is removed and removed, the door can be closed, and it is not allowed to close normally, to avoid damage to the oil pump caused by the oil pump sucking.

- The fuel tank should be replaced with new oil every 2,000 hours of operation. In special circumstances, if the oil is continuously overheated or contaminated to deteriorate the oil, it should be replaced immediately.

- The oil in the fuel tank should be kept at a certain temperature, but it should not exceed 70 degrees. If it is over 70 degrees, check if the equipment is abnormal.

Anchor Drilling Rig Manufacturer – YG Machinery

Henan YG Machinery is a leading supplier in China, committed to providing customers with the fastest quotation, the best quality products, the most competitive prices, and the fastest delivery may be drilling and road construction machinery products industry standard specifications and customer requirements. We are an expert in this field, 100% committed to providing quality and price-unmatched products, to provide customers with quality, effective service. In YG machinery, we also sell rock drills, water well drills, pile drivers, core drilling rigs, down-the-hole drilling rigs, portable water well drilling rigs, crawler-mounted water well drilling machines, trailer water well-drilling rigs, tractor drilling rigs, truck-mounted drilling rigs, horizontal drilling rigs, rotary drilling rigs, etc. So if you are looking for drilling equipment, please feel free to contact us now, and we will give you the best service.【WhatsApp/WeChat/Phone/Skype】+86 136 1385 6800